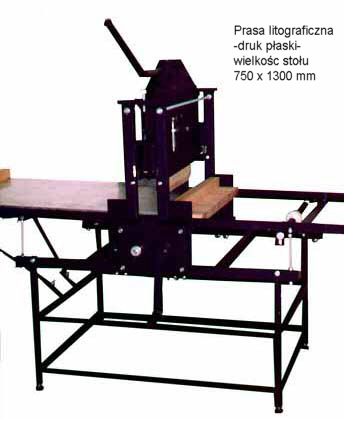

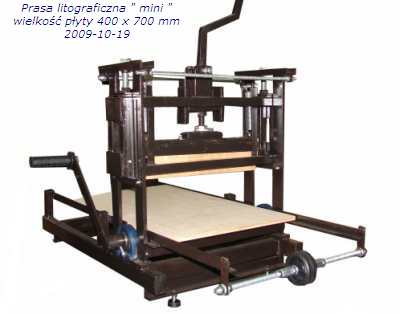

THE LITHOGRAPIC PRESS - INTAGLIO

The

lithographic press is made in the dimensions chose individually by the client.

The dimensions of the press bed (table) are treated as a criterion of the press

size. We offer two kinds of the lithographic press - the stationery one and

that, which is fitted with two shelves, designed for the printing products,

tools, etc. The press bed (table) overall dimensions are available in the range

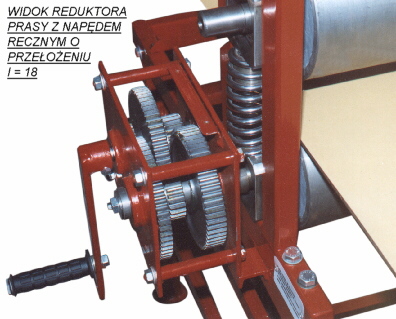

of 400 600mm to 750 1300mm. Moreover, there is manual drive with the length

changeable crank handle. The gear ratio range of the toothed gear transmissions

varies between i=6 and i= 12(24). The lower working roll is made of the

thick-walled steel pipe (the external diameter o170mm and the thickness of the

wall b=17mm) with the braces welded inside, and the bearing journals with the

diameter o35mm. The lower pressure shaft is bearing on the roller bearings

situated in the dustproof mounts, what causes, that the efficiency of a machine

is very high (the shaft rotates slowly). The press bed (table) is made of the

impregnated wood in timber form on "a leaf spring" with the thickness

30 ÷ 50mm. Depending on the press size, the maximum pressure of the skid varies

between 600 and 1200 kG. The travelling of the skid during "the

closing"s of the press is h=30mm whereas the range of pulling out of the

skid is s=80mm. The maximum distance from the skid edge is H=150mm. The

construction is made of the welded, thick-walled and cold-rolled metallurgical

profiles. The finishing touch is to paint the press, rustproof coat or every

other color selected by the client. If the dimensions of the press bed are 750

x 1300mm - the press weight varies between 85 and 250 kg

Note:

1. It is a possibility to assemble the hydraulic cylinder pressing

the skid (fitted with the adjustable downforce) , to the press with the large

overall dimensions of the press bed (table)..

2. Upon request, there is also a capability to make the steel

rubber-lined shaft with the hardness 65 sh, which is fixed variably with the

skid. It is used to printing the large black and white or multicolored

relief printings..

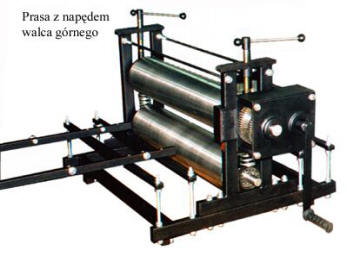

THE GRAPHIC ROLLER PRESS |

|

A

- Working roller diameter |

|

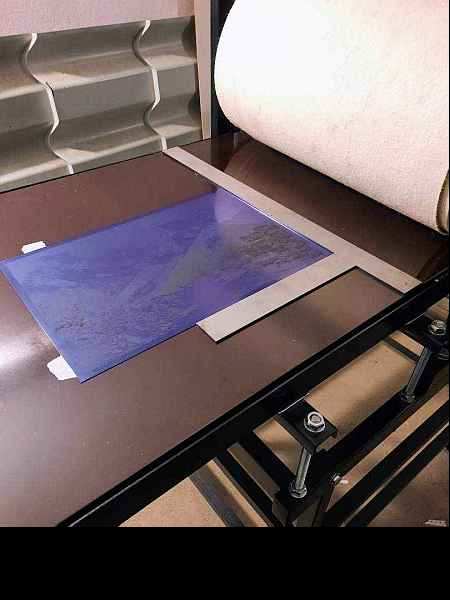

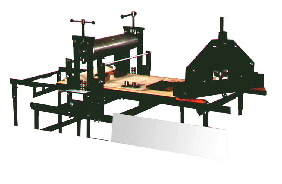

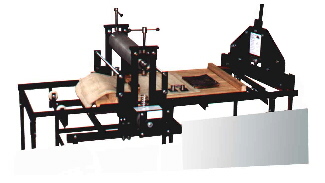

A press

designed for printing with steel matrixes is used to print with copper and zinc

coating matrixes with thickness up to 5 mm. The upper roll stroke is h=50mm.

The raising of the pressure roller is automatic with the use of the helical

spring. Moreover, there is the manual drive with the crank handle. .

Offering presses are available in two versions:

- with the lower roller drive;

- with the upper roller drive.

The work plate is made of cold-rolled steel sheet (thickness

b=3mm) or made of plastic /option/. The overall dimensions of the plates are

equal with the overall dimensions of the graphic format, or are individually

chosen by the client. [450*600mm\ 600*1000mm\ 750*1300mm\

820*1400mm\1200*2000mm]. The working rolls are made of the thick-walled pipes

(with external diameter o170mm, the thickness of the wall g=14mm and the welded

inside bracing rings made of sheet steel g=6mm). At the ends of the pipes there

are welded inside bearing journals with the diameter o50mm. The shafts are

bearing on the ball bearings with own reserve of grease (unattended). In the

case of large presses, the shafts are bearing on the roller bearings. The gear

ratio range is depended on the press overall dimensions plus the client's

directions and fluctuates between i=6 and i=18. The pressure of the working

roll is smoothly regulated and varies between P=0 and 700kG.

The presses are being made in assembly versions, as a:

- designed for fasten on the "own"

press bed (table) - an integral part of the press;

- designed for fasten on the "foreign"

press bed(table) - not an integral part of the press.

The whole construction is made of the thick-walled and cold-rolled

metallurgical profiles. In addition, the construction of the press allows for

the complete dismantle (it lets for easy transport and what is more important,

that press could be placed in adopted studios, e.g. a loft). The press is

painted black or other color chose by the client. The weight of the discussed

kind of the press varies between 50 and 250 kg (depending on the size). .

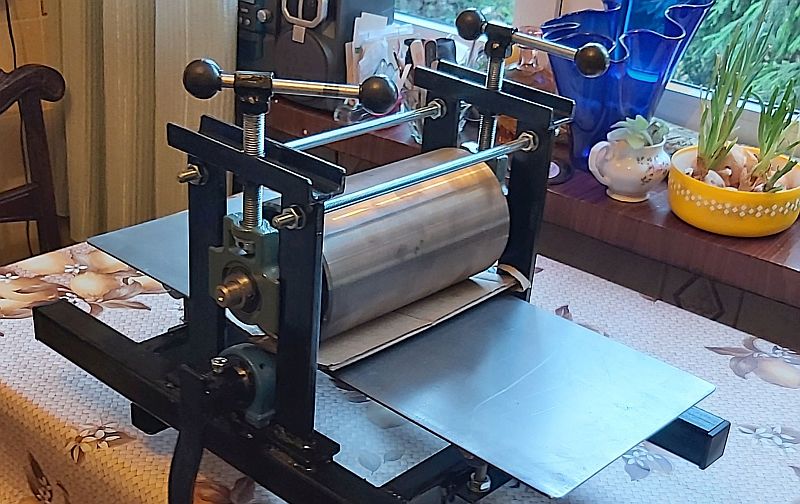

Press

witch up roller drive

Press professional with plate 450 x 600 mm

Press with plate 1250 x 2500 mm ratio i= 18 and

both rolls drive.

Prasa o wielkości 1300 x 3000

mm z płytą fenolowo papierową i=18

Press with

plate 750 x 1300 mm / 450 x 600 mm / and nets for drying graphics

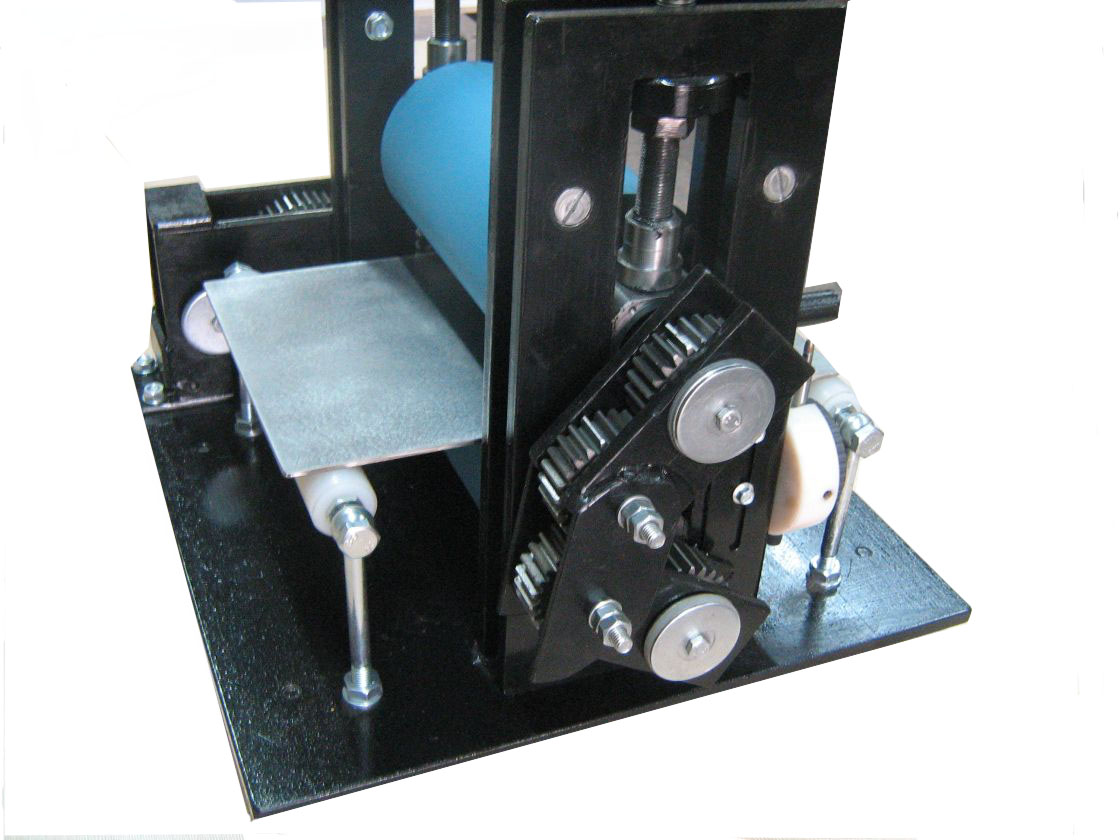

For students, pupils, and other people who need the " "mobile

press" (e.g. during the participation in workshops, etc.)

there are two kinds of the lighter press :

- the press designed

for " ExLibris"

- the press intended for students :)

Technical

parameters of the press for "ExLibris" - Technical parameters :

1-the upper roll diameter 120mm [max 150mm]/ a thick-walled pipe

2-the lower roll diameter 40mm

3-the gear ratio i=3-4

4-the manual drive

5-the rolls width B=250 to 400mm [max 600mm]

6-the plate lengthen L=400 to 600mm [max 1000mm]

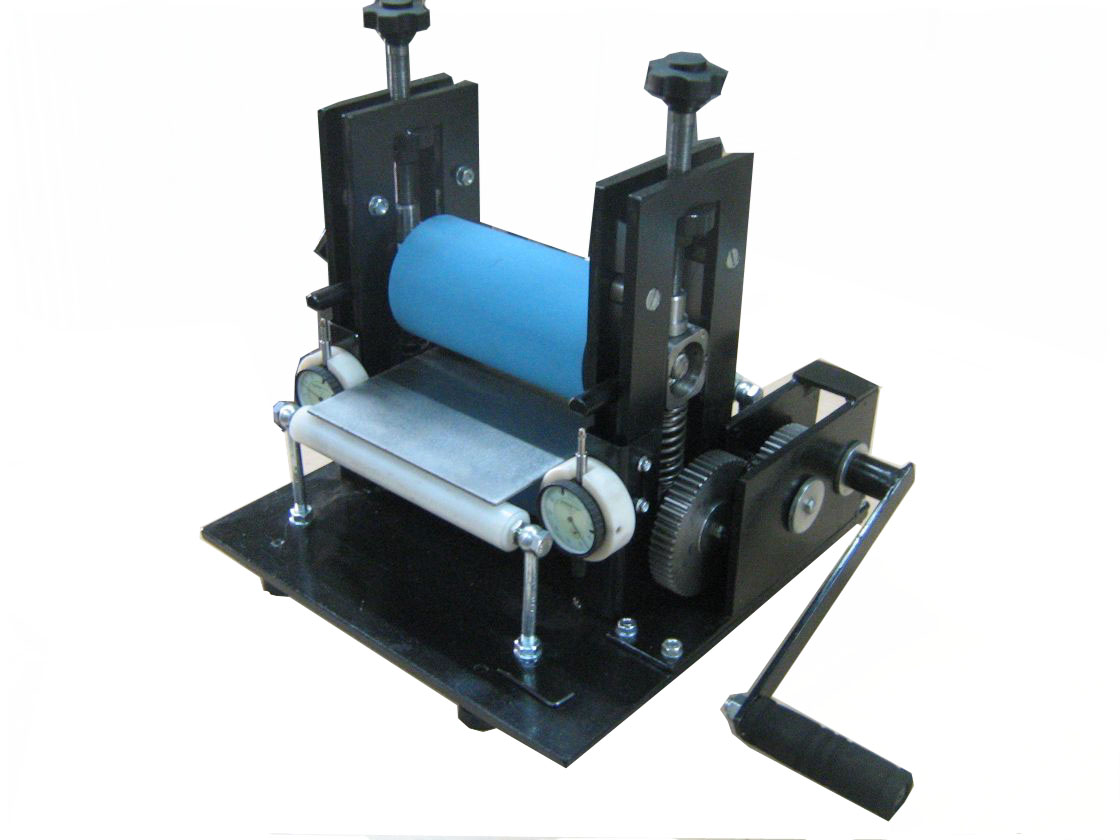

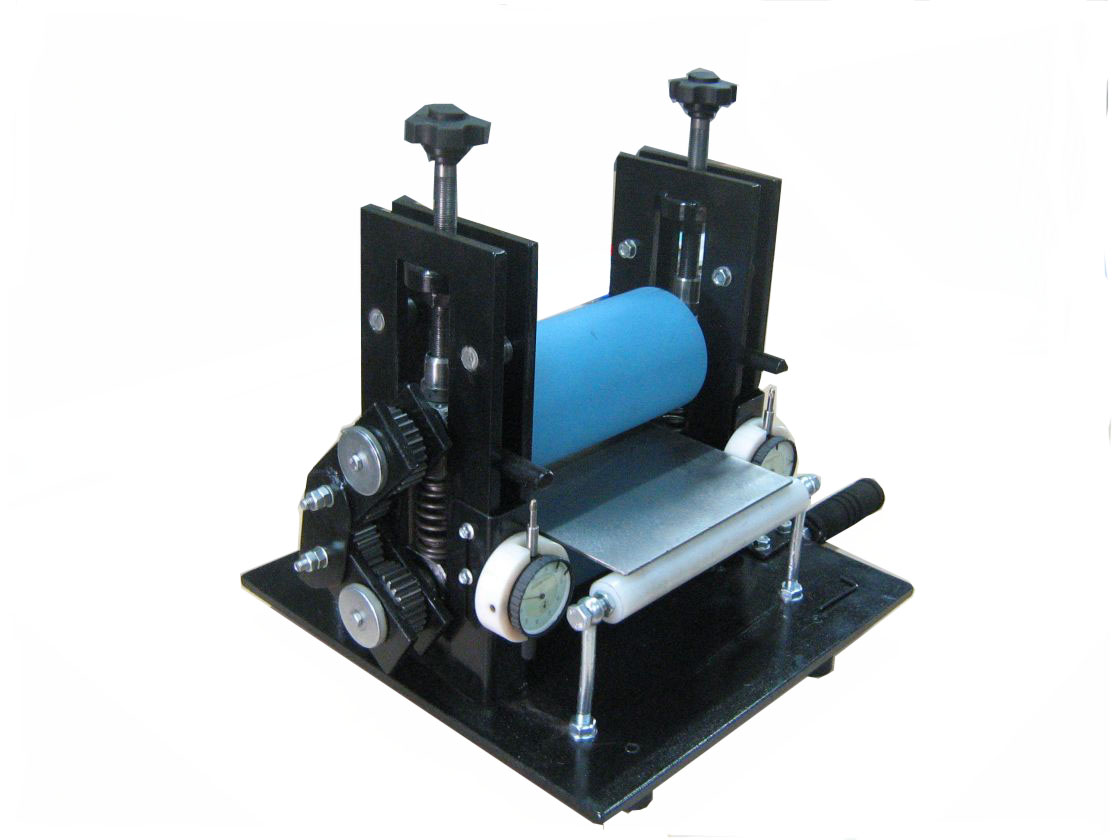

Press for

students - THE NEW ONE - Technical parameters:

1-the upper roll diameter 100mm/ steel shaft

2-the lower roll diameter 30mm/steel shaft

3-the gear ratio i= ~3

4-the manual drive

5-the rolls width B=200 to 250mm

6-the plate lengthen L=300 to 450mm

ExLibris press with plate 350x500 mm / 500 x 700 mm /

Below,

there is presented the new little press for students. It is very similar to the

press - type

"ExLibris

- but is lighter and equipped with the bearings. That press weights about 20-25

kg.

Press for students with plate 250x500

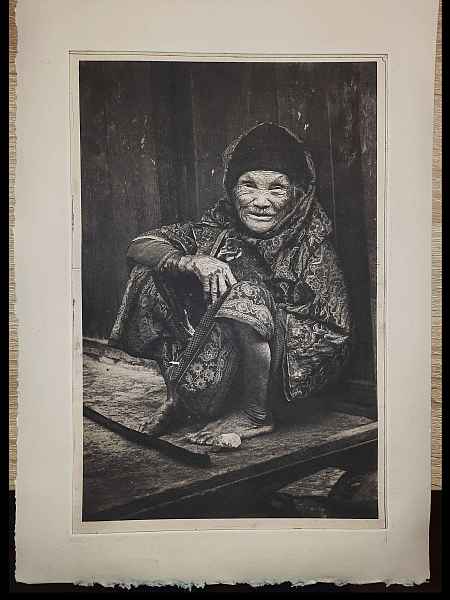

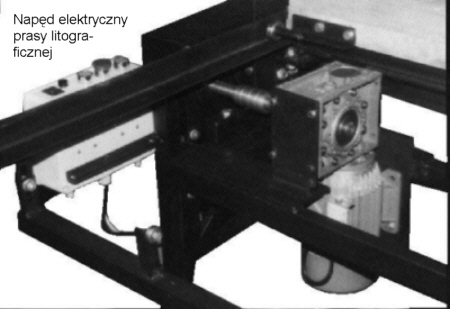

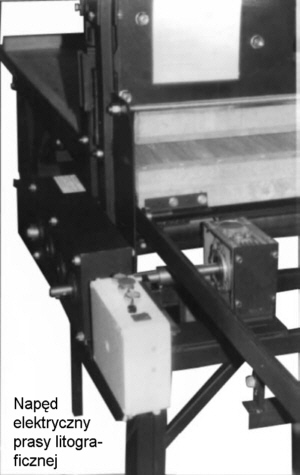

THE GRAPHIC PRESS WITH THE BOTH ROLLS DRIVE

- electric drives

The press with the enlarged

working roll stroke and the synchronous drive of both rolls (as well the

working roll as the pressing down one) is a special kind of the press, which

lets to make graphics from the steel matrixes or printing from the linocuts,

the woodcuts and the plastercuts. It is possible, thanks to the enlarged size

of the working roll stroke to h=80mm, the smoothly regulated pressure of that

roll and the cinematic coupling of both rolls (with the same external

diameter). The synchronous drive of both rolls is being performed by two gear

transmissions. Discussed presses are built in optional dimensions with

designing for assemble on the press bed or on each other table designed for it.

The pressure of the working roll varies between 0 and 7000kG and is smoothly

regulated. Moreover, there is the manual drive with the crank handle (with the

changeable length of the arm) whereas dependently on the dimensions of the

desk, the gear ratio is in the range of i=6 to i=18. The press weight is

depended on its size and the construction (whether with the press bed (table)

or without) and fluctuates between 180kg and 250kg. The work plate is made of

steel sheet (thickness g=3mm) or textolit /option/. The diameter of the working

rolls is o170mm and the rolls are made of the thick-walled, ribbed steel sheet

(thickness g=6mm) pipes. The tolerance of the working rolls external diameter

is +/- 0,05mm.

Napęd

elektryczny z motoreduktorem o przełożeniu i = 40 i pasem zembatym / cichobieżna/

Prasa "ortopedyczna" do walcowania formatek.

Prasa "ortopedyczna" do walcowania formatek.

Prasa do walcowania formatek płyt akumulatorowych - Instytut Ogniw w Paznaniu

THE GENERAL-PURPOSE PRESS (WITH THE ATTACHMENT

TYPE-'LITO')

The

general-purpose press gives an opportunity to make graphic copies from steel

matrixes (copper, zinc) and printing from the lithographic limestone. That type

of press is characterized by the first degree of the general-purpose, what

means that it combines features of the press designed for "steel"

with the lithographic one. That press also allows for printing from steel

plates (thickness= 5mm). Furthermore, dismantling the pressure upper roll and

replacing it by the attachment type "Lito", there is a possibility

for making graphics with the lithographic technique. In order to use both: the

working roll and the attachment type "Lito", the main construction

requirement is to fitted the general-purpose press with the "own"

press bed, what means that the press table must be the integral part of the machine.

The general-purpose press is made in the same way as the previews ones, namely,

in the dimensions chose individually by the client. There is the manual drive

with the crank handle. The gear ratio range is depended on the press overall

dimensions plus the client's directions and varies between i=6 and i=18. If the

dimensions of the work bench are 750 x 1200mm with thickness g=30mm - the press

(including the attachment type "Lito") weights about 300kg. The

technical parameters of the general-purpose press are the same as the

parameters of the lithographic and the graphic press..

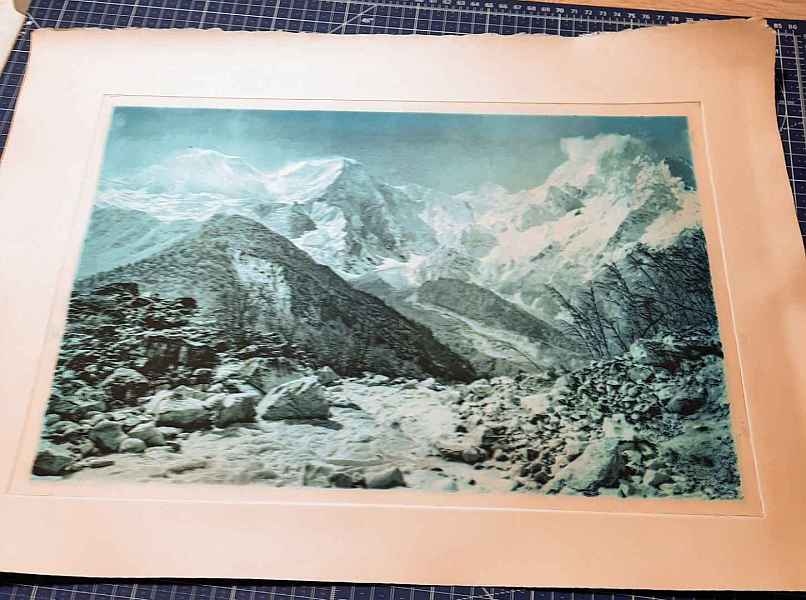

The

press type "COMPACT" is characterized by the second degree of the

general-purpose. It gives an opportunity to make copies in all techniques of

the intaglio printing as well as from steel matrixes, the woodcuts, the

linocuts and the palstercuts. Moreover, dismantling the upper roll and

replacing it by the attachment type "Lito", the press transforms into

the professional lithographic press. The working rolls (the diameter o170 mm)

are made in tolerance +/- 0,05 mm and are cinematically coupled - what lets to

make the accurate and multicolored graphics. The exerted pressure of the

pressure roll is being smoothly regulated and fluctuates between 0 and 7000 kG.

The pressure of the lithographic press skid varies between 0 and 1000 kG. The

maximum height of the pressure roll is 100mm (max 200mm). The maximum distance

of the lithographic skid from the table's surface is 150mm, whereas the skid

stroke during pressing down is 30mm. The range of the skid lowering is 80mm.

There is also the manual drive with the crank handle. The gear ratio range is

depended on the press dimensions plus the client's directions and it varies

between i=6 and i=18. If the dimensions of the table (the press bed) are 750 x

1200mm � the weight of the press with the

attachment type "Lito" is 350kg. Because of the construction

requirements, the press type "Compact" is built only with the

integral press bed (table)..

Note:

The press is

designed for printing the large graphics by the relief printing with use

(changeably with the lithographic skid) . The gummed steel

shaft (hardness 65 StH).

ASSENBLY OF PRESSES AT THE CUSTOMER'S - option

At the customers reqest, We deliver and assemble presses anywhere in Europe :)

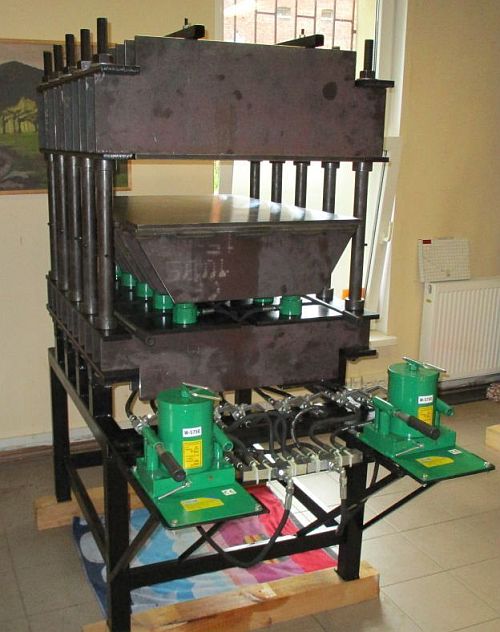

Jednotłokowa

prasa dociskowa 300x400 mm 20Ton

Dwa zdjęcia prasy dociskowej o

wielkości płyty 800 x 1200 mm i wartości siły docisku 60 ton / 600 [kN]

Prasy dociskowe do druku wypukłego budowane są jako stacjonarne

prasy z siłownikami hydraulicznymi oraz

ruchomą płytą dolną wykonaną ze stali o grubości ~20 mm oraz górną

płytą stalową, która na stałe jest zamocowana

do korpusu prasy.

Docisk realizowany jest przez ręczne pompowanie oleju

hydraulicznego za pomocą pompy do siłowników

hydraulicznych. Pompa hydrauliczna wyposażona jest w manometr

który służy do pomiaru wartości ciśnienia

panującego w siłownikach hydraulicznych. Za pomocą tabeli

przelicza się wartość ciśnienia oleju hydraulicznego

na wartość siły docisku prasy.

Wielkość stołu ustalana jest bezpośrednio z zamawiającym,

wielkości stołów zawierają się w zakresie:

od 300 x 400 mm do 800 x 1200 mm a wartości sił docisku od 20 Ton

/ 200 [kN] do 60 Ton / 600 [kN]

Maksymalny rozstaw płyt dociskowych wynosi ~140 mm. Waga pras

dociskowych wynosi odpowiednio

od 60 do 550 kg i zależy od wielkości prasy.

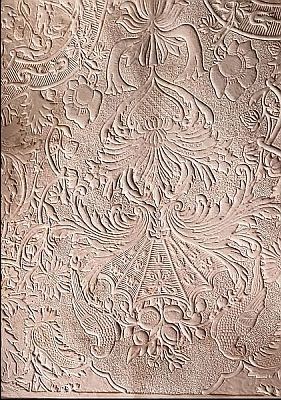

Poniżej prasa od tłoczenia kurdybanów, o wielkości płyty 700 x 1000 mm o docisku sekwencyjnym

sterowanym zaworami. Maksymalny docisk 120 [ Ton ] - 1200 [kN]

Montaż prasy

Prasa zmontowana

Przykładowe kurdybany tłoczone na prasie

Legenda A - B

A - The basic length of the roller

B - The total length of the roller (with handles)

C - The diameter of handles

D - The thickness of the applied rubber layer

Approximate prices (in 2023 yr).

Rubber covered printing rollers the hardness = 35sh .

The diameter :

A : the external diameter Ǿ=80mm

|

Length |

Ǿ external roller = 80 mm / Thickness of rubber [ mm ] D= |

|||

|

Prices [pln]-gross |

D = 5 mm |

D = 10 mm |

D = 15 mm |

D = 20 mm |

|

L = 150 mm |

350 pln |

650 pln |

850 pln |

980 pln |

|

L = 200 mm |

460 pln |

850 pln |

1180 pln |

1480 pln |

|

L = 250 mm |

570 pln |

980 pln |

1480 pln |

1780 pln |

|

L = 300 mm |

680 pln |

1180 pln |

1780 pln |

2180 pln |

B : the external diameter Ǿ=60mm

|

Length |

Ǿ external roller = 60 mm / Thickness of rubber [ mm ] D= |

|||

|

Prices [pln]-gross |

D = 5 mm |

D = 10 mm |

D = 15 mm |

D = 20 mm |

|

L = 150 mm |

250 pln |

450 pln |

590 pln |

730 pln |

|

L = 200 mm |

340 pln |

590 pln |

790 pln |

970 pln |

|

L = 250 mm |

420 pln |

750 pln |

990 pln |

1180 pln |

|

L = 300 mm |

480 pln |

890 pln |

1180 pln |

1450 pln |

Printing rollers

are made in two versions:

A- to apply black paint

B-to apply colorful paints (to multicolored graphics).

The offer kinds of the printing rollers are available in various

diameters, lengths and the various thicknesses of applied rubbers. Nowadays,

the printing rollers are made accordingly to the client's directions. Offering

rollers are covered with offset rubber (hardness 35sh) which the

physicochemical parameters are intended for as well as black and colored

paints. The thickness of applied rubber varies between 5 and 20mm (the thicker

layer of rubber the better "adjustment" of the roller). Besides, if

the thickness of applied rubber layer varies between 10 and 20mm, there is a

possibility to renovate the roller by the grinding (up to 5 times). The length

of the printing rollers for: - black paint fluctuates between 100 and 600mm

with the external diameter o80mm. - colorful paints fluctuate between 50 and

350(400)mm with the external diameter o60mm. - the margins fluctuate between 5

and 50mm with external diameter o40mm. On request, there is an opportunity to

make the rollers with the hardness up to 90 sh.

Warning:

All kinds of the printing rollers made of

offset rubber should be cleaning liquid

paraffin or turpentine. The use of petrol or any other solvent can cause

the damage of the rollers!

Piece wykonane dala Instytutu

Sztuki UMK w Toruniu 900 x 1100 mm temp. grzania 350 St C

Offering

electric heater fitted with the thermostat (using to heat the graphic plates)

is made in various dimensions - the maximum size is 750 x 520mm. Depending on

the size, the heating power is in the range of 1000W and 2500W.

The range of the temperature control varies between 60 and 120°C.

. The external plate is made of steel and the factor responsible

for the transport of heat from the heaters to external surface of the plate is

chamotte. The elimination of the factors transporting heat (such as water and

transformer oil) and the use of the heaters in "dry" conditions lets

to raise up the machine efficiency and reliability as well as the comfort of

using. The sensitivity of the thermostat is +/- 2,5°C - what lets for even

distribution of the heat on the plate's surface. The heater is fitted with the

current protection and the fire protection in accordance with PN, and

additionally is supplied with the connection to electricity control and the

heat control. Below, the basic

Dimensions

of the heating press platen with the prices on 2023 yr / gross /

THE PLATEN DIMENSIONS

PRICE [pln] - gross

400 x 500 mm / 120-220 StC

2800

500 x 600 mm / 120-220 StC

3200

700 x 800 mm / 120-220 StC

3900

800 x 1000 mm / 120-220 StC

4900

zz

WIDTH X LENGTH

900 x 1100 mm / 350StC 11500

The sculptor's kawalet (table) is made

according to the client's directions. The picture shows the tables with the

rounded tops (the diameter o350mm). Those ones were made to order.

Additionally, there is a possibility to make the table with the square or

rectangular top with various dimensions. Moreover, there is also an opportunity

to make the kawalet intended for the heavy and large sculptures placed on the

floor. The kawalet's top is bearing on the thrust bearings and the rotation

interlocking mechanism.

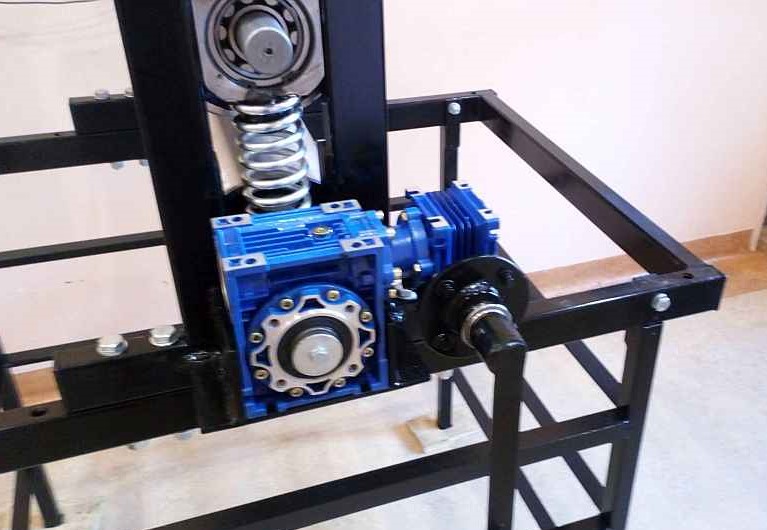

MOTOREDUCERS-THE MECHANICAL AND ELECTRIC

SETS TO THE PRESS DRIVE

The

special equipment of all kinds of the press are the auxiliary mechanical

transmissions with the electric motor intended for the press drive. They are

assembled as additional ones, inspite of the manual drive. The special coupling

lets for the changeable press drive: manual or mechanical. The set of

motoreducers is fitted with the overload friction clutch and the set of the

limit switches. The ratio varies between i=25 and i=40. The master switch is

equipped with the protection key. The power of the set fluctuates between 1000W

and 1500W and is supplied by 220 Voltage. .

LITHOGRAPHIC PRESS jj

There

is a possibility to use the hydraulic pressure set as the additional equipment

in the lithographic presses. That set consists of the hydraulic motor, the gear

pump with the electric drive and the section and overflow valve, the pressure

conduit, the protection tank and the electric controller. That set is assembled

instead of the conventional mechanic pressure. The gear pump presses the oil

through the safety-valves and the overflow valve into the distributor,

connected with the pressure skid of the press, which is responsible for the

raising up and the lowering of the cylinder. The pressure power is being read

off from the manometer. The pressure power is smoothly regulated with the use

of the overflow valve. The set is supplied by 220 Voltage and is equipped with

the protection key.

THE TROLLEYS, THE DRIVERS AND THE STATIONS TO THE LITHOGRAPHIC STONE GRINDING

The

lithographic stones need the periodic grinding and smoothing. Because of the

large weight of the lithographic stone we offer the special set of devices

designed for the grinding and the transport of the lithographic stone. The set

consists: - the trolley equipped with the roller top intended for the movement

of the stone to the press and back. The height of the top is regulated and id

fitted with four wheels (two with braces). - the set for the stone grinding

consists of the table with the wooden framework and the tank for water with

decanter. On the table side there are elements to attach the hose and remove

the water, and the additional shelve.

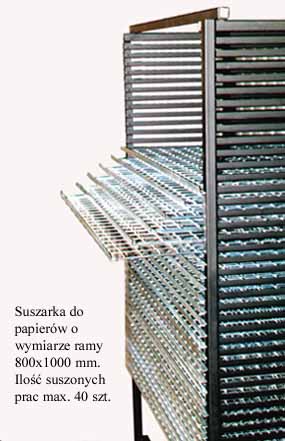

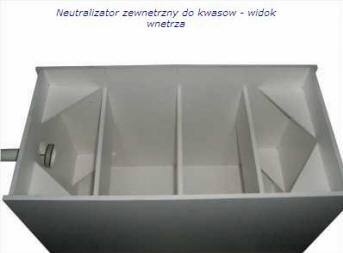

THE PAINT TRAYS, THE ACID NEUTRALIZATORS AND THE WORKSHOPS TABLES

The complement of the offering

products are the paint trays designed for soaking the paper and etching steel

plates. The paint trays are made of both: sheet aluminum and sheet acid-proof

and are available in various sizes from 750x1200x100mm to very small ones.

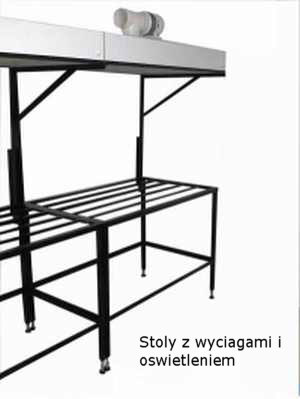

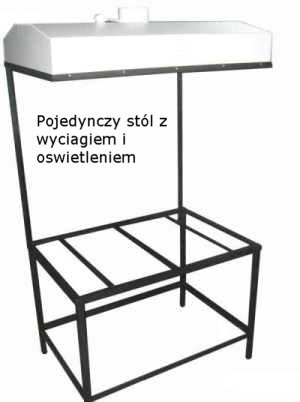

Moreover, there are produces additional tables (stable or moveable) fitted with

the shelves of the drawers designed for paper and printing paints. Those tables

are made as stable, removable or raised with the frameworks intended for drying

the papers.

1.The students "press";..250*500 mm ( 300 x 600 mm ).......... 2700 - 2900 - PLN

2.The graphic press type "ExLibris" .350x500mm./500*700mm/. 4100 - 5300 - PLN

3. The graphic press .750*1300 mm.......................................8100 - 9500- PLN

4. The lithographic press .....................................................8000 - 11500 - PLN

5. The graphic press with the attachment type "LITO"

............12900 - 13700 - PLN

6. The graphic press with both rolls drive ..............................8200 - 9800 - PLN

7. The press type "COMPACT"

.............................................12000 -

15700 - PLN

8. The pressure press ........................................................8100 - 51000 -PLN

9. The painting rollers ............................the price sets with the client

10. The electric heaters .......................................................2500 - 10500,- PLN

11. Sculpture table

...............................................................750 - 1100 PLN

12. Motoreducers..................................................................6100 - 8800 - PLN

13. The hydraulic pressure sets to the lithographic presses .......5200 - 10500 - PLN

14. The trolleys .................................................................3500-

do 5500- PLN

15. The paint trays, the workshops' tables

.................

the price sets with the client

16. The system of the paints hanging

..........................he price sets with the client

17. Upon request .....................................the price sets with the client

The price list is actualy on 2024 yr / price BRUTTO

All prices can be negotiate

There is an opportunity

to make various elements based on the client's projects or

the elements or machine patterns

gave as the technical documentation

or the photos.

The examples of the presses configurations and their prices.

on 2023 -24 yr

NO. |

THE PRESS CONSTRUCTION |

THE PLATE DIMENSIONS

|

|||||||

1 |

-

-steel work plate |

Price : = 8100 pln |

Price: without a base |

Price : without a base |

|||||

2 |

The same as above plus |

Price : |

Price: without a base |

Price: without a base |

|||||

3 |

The same as in 1 and 2 plus |

Price : |

|

|

|||||

The mechanical and toolmaker workshop of engineer Wojciech Zawadzki also offer:

- the full fittings of the studios for graphic techniques;

- service and renovation of all kinds of graphic presses;

- the adaptation of the old presses for the new needs;

- the works make according to the client's directions;

- the works make according to the client's directions;

Additionally: :

- the mechanical metalworking;

- heat and chemical treatment of metal (coaling, nitriding);;

- the welding works;

- the toolmaker works;

- the designing and constructional works in the field of mechanics and electrotechnology.

If any questions, write please:

e - mail :

or call::

tel.

+48_ 62 _ 764-65-79.

tel. kom.

+48_602-873-313 (mobil tel. )

PRAS - GRAF .

ZAKŁAD

ŚLUSARSKI

inż.

Wojciech Zawadzki

ul. Grunwaldzka 16

62-800 KALISZ

Polska /Poland /

Opracowanie witryny: Wojciech

Zawadzki

e-mail: zawadzki@infocentrum.com